Lightweight Concrete

Concrete on the outside, light on the inside

These concrete panels fit perfectly in an industrial and cool interior. The top layer of the lightweight concrete panels shows the typical characteristics of concrete and provides it with its own character. We apply the lightweight concrete to various panels such as plywood or MDF. It is also possible to further process the 1.5 mm concrete slabs yourself. The panels are easy to cut to size without increased tool wear.

Many design options with Lightweight Concrete

The blow holes, color shades and fine cracks are typical characteristics of concrete. The 1.5 mm concrete slabs are indistinguishable from solid concrete. It looks and feels like ‘real’ concrete and is easy to use for many design options. Consider, for example, wall panels for trade fairs, shops or offices. Combine the Light Concrete panels with the Acoustic RibPanels or the Acoustic Grilles. Wood and concrete complement each other perfectly. Would you like advice about the possibilities? Contact us!

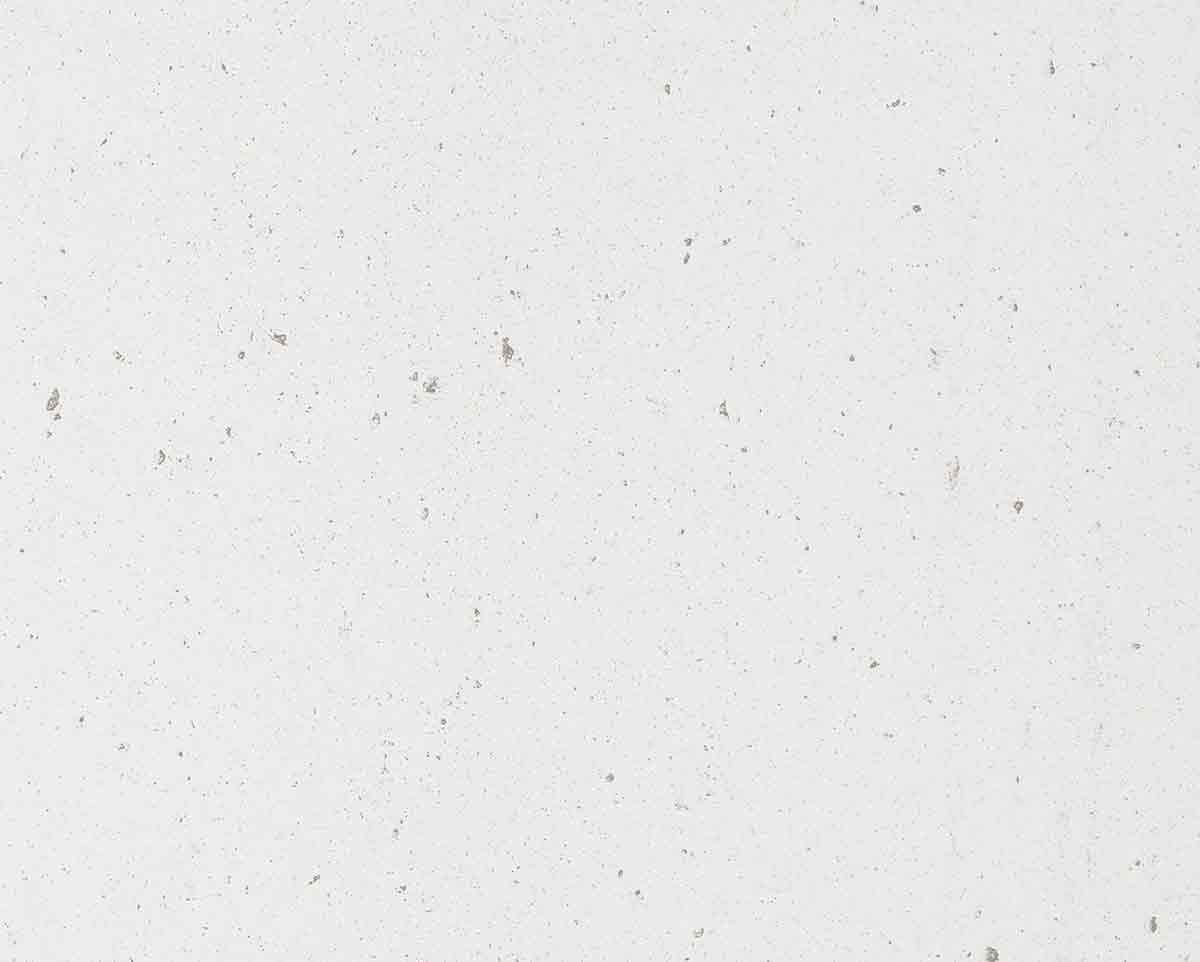

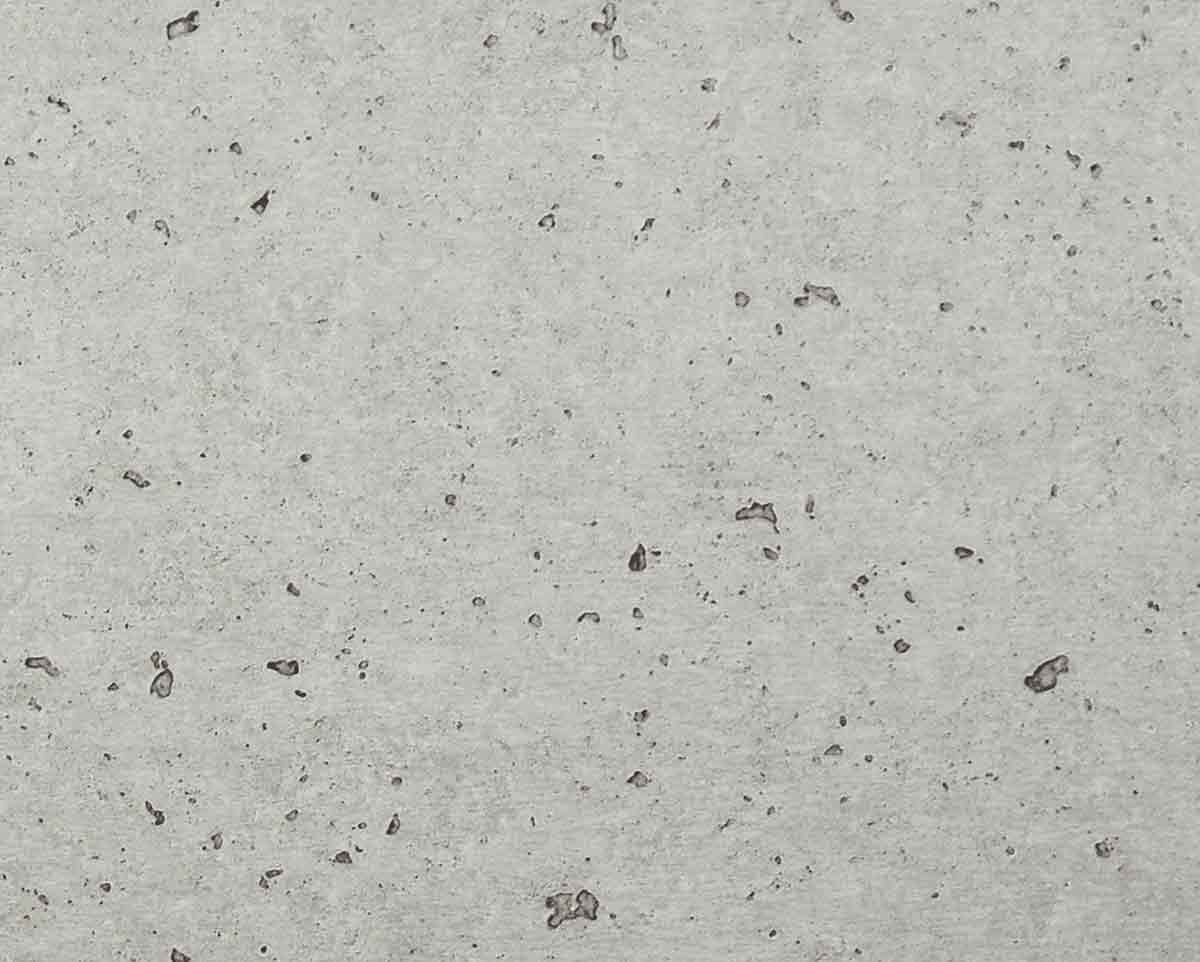

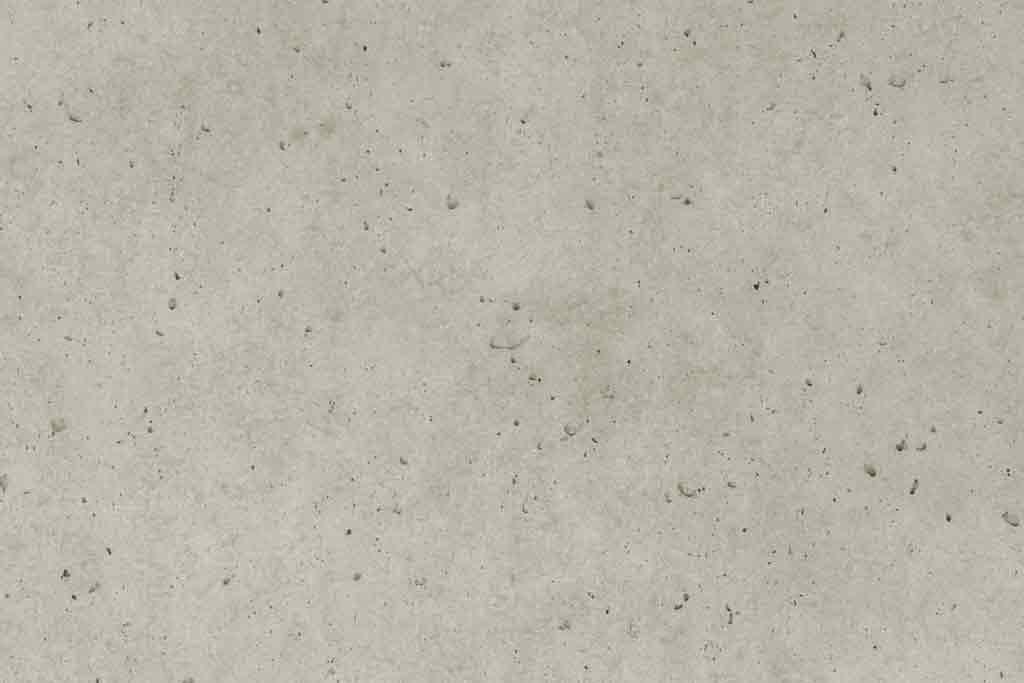

Classic grey

Classic anthrazit

Authentic

Formwork

Classic white

Retro

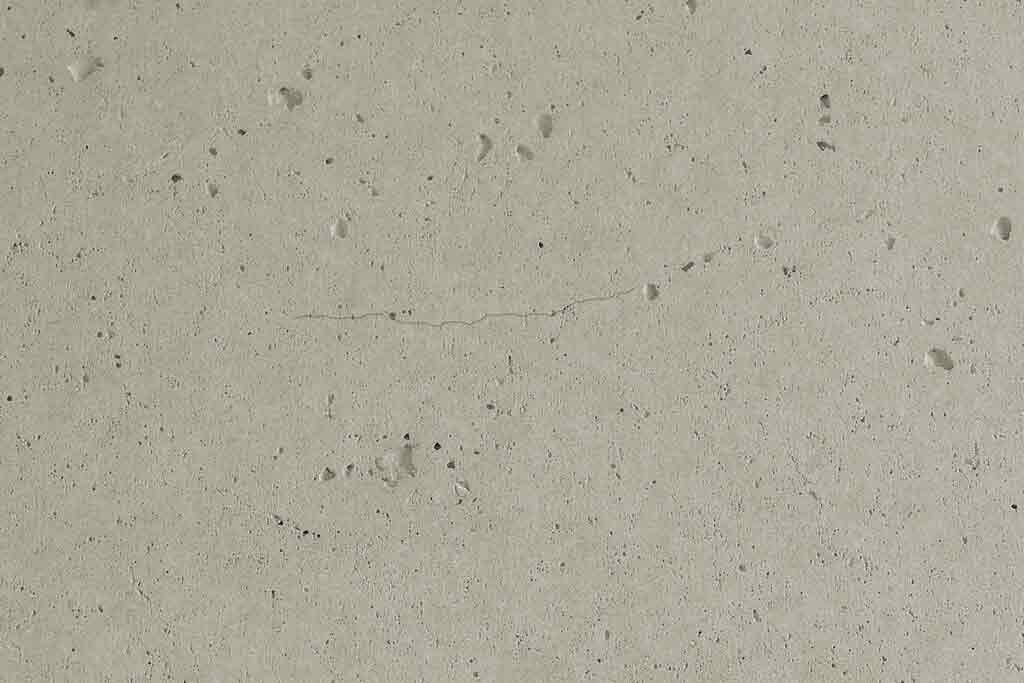

Characteristic properties of concrete

Our concrete panels show the authentic characteristics of real concrete: shrink holes, color shades and fine cracks. Once processed, it is indistinguishable from solid concrete. The look and touch are the same as ‘real’ concrete. Quality you can see and feel down to the smallest detail. This makes our Lightweight Concrete really special.

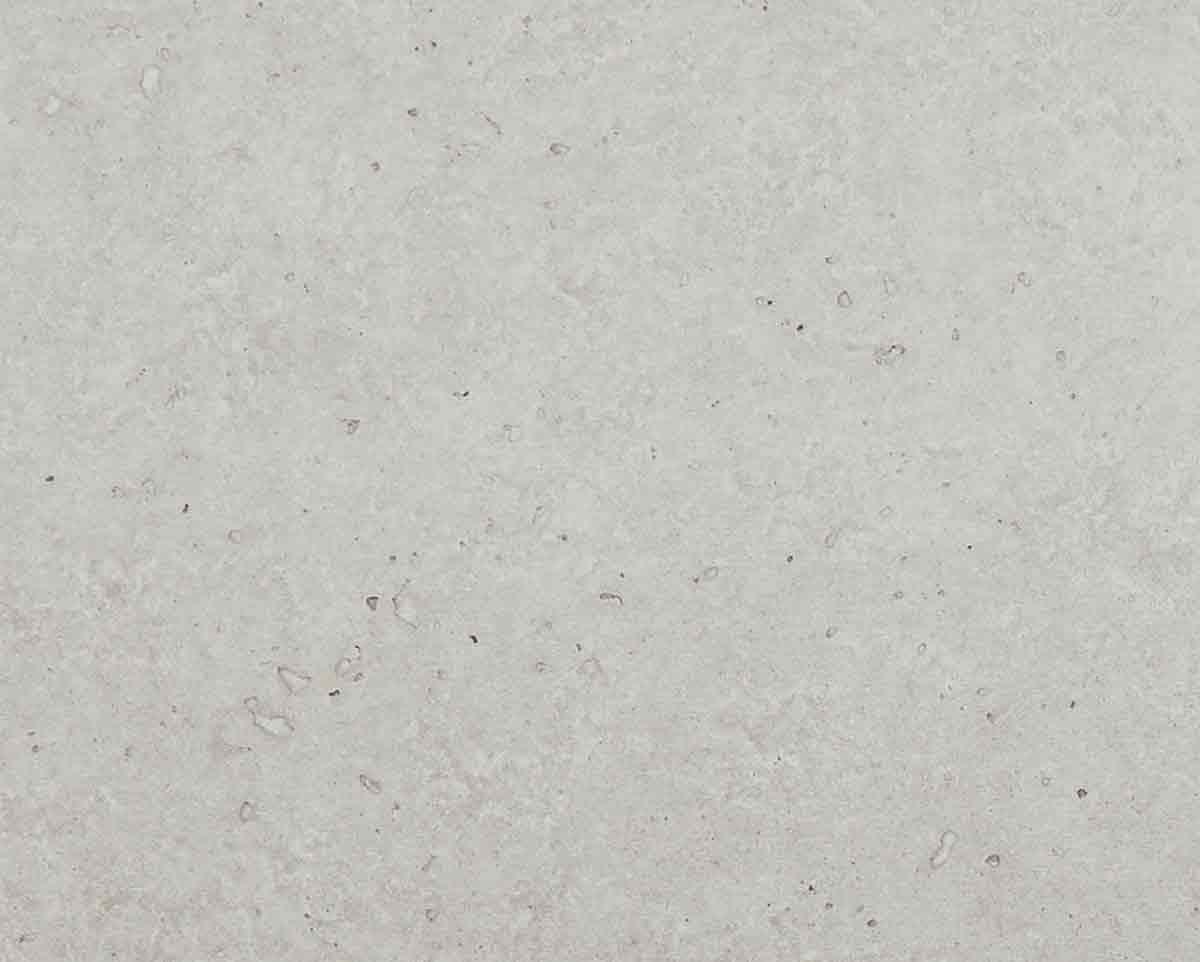

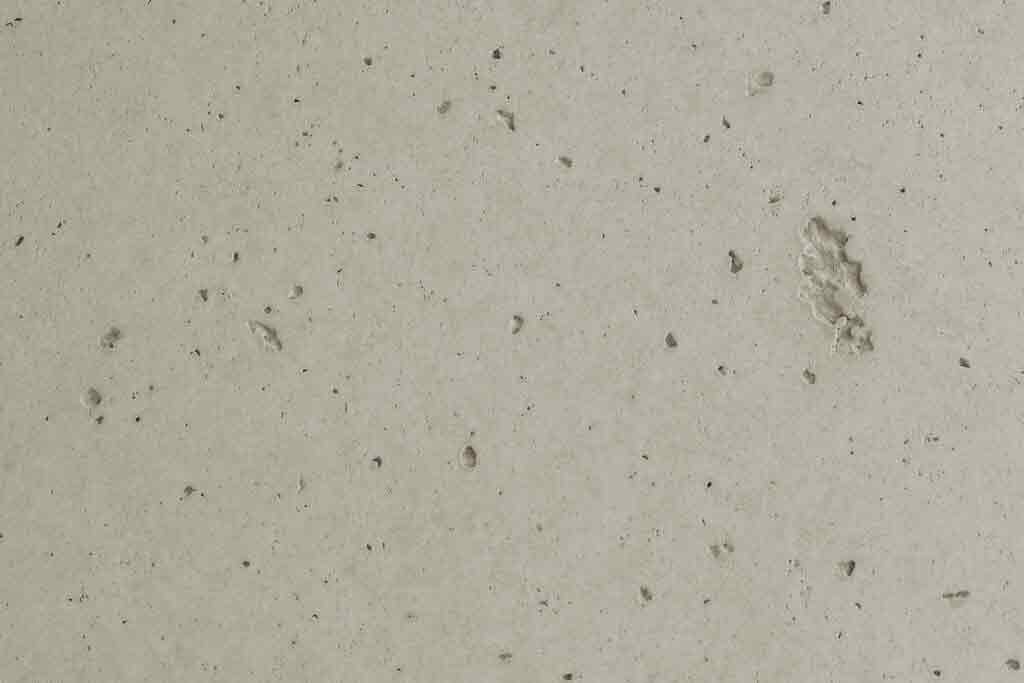

Shrink holes

Typical air holes, deep structure and original aesthetics of concrete.

Hairline cracks

Occasional hairline cracks are typical of concrete.

Colour fluctuations

Different colors and nuances that ensure the authenticity of the concrete.

Choice of different finishes Lightweight concrete

In addition to the standard 19 mm panels, we also supply Formwork, Pur and Acoustic panels. Download the brochure ‘LightBeton’ for detailed technical data.

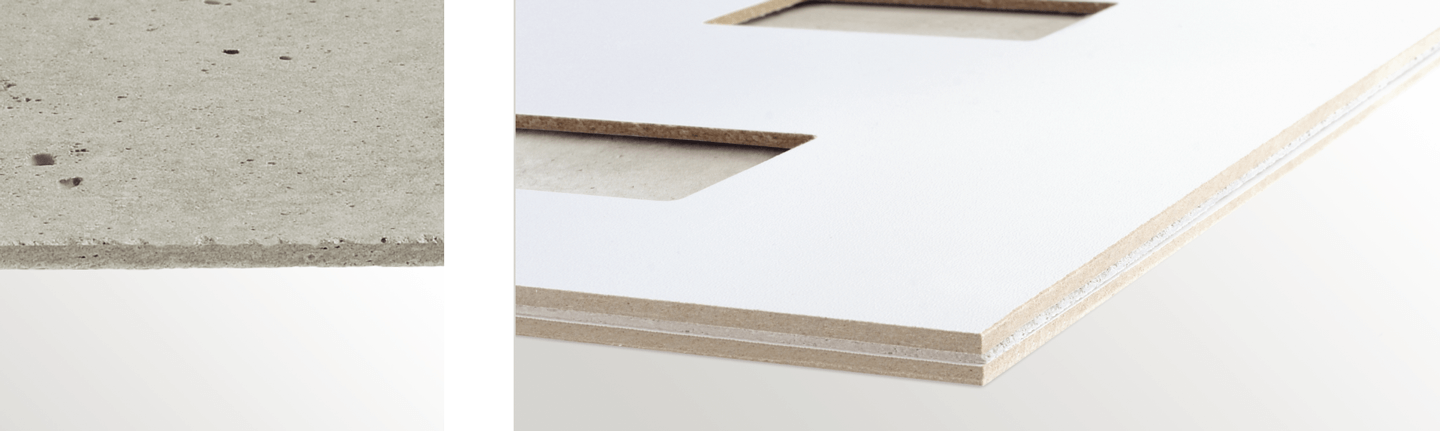

Lightweight Concrete standard panel 19 mm

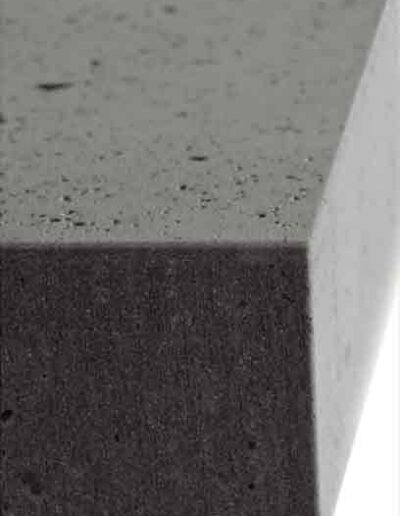

The standard 19 mm Lightweight Concrete panel consists of an MDF panel with a 1.5 mm Lightweight Concrete plate on both sides. This ensures a maximum weight of 2.25 kg/m2. This is a weight saving of up to 90% compared to a real concrete wall. Fire resistant according to DIN EN 13501-1.

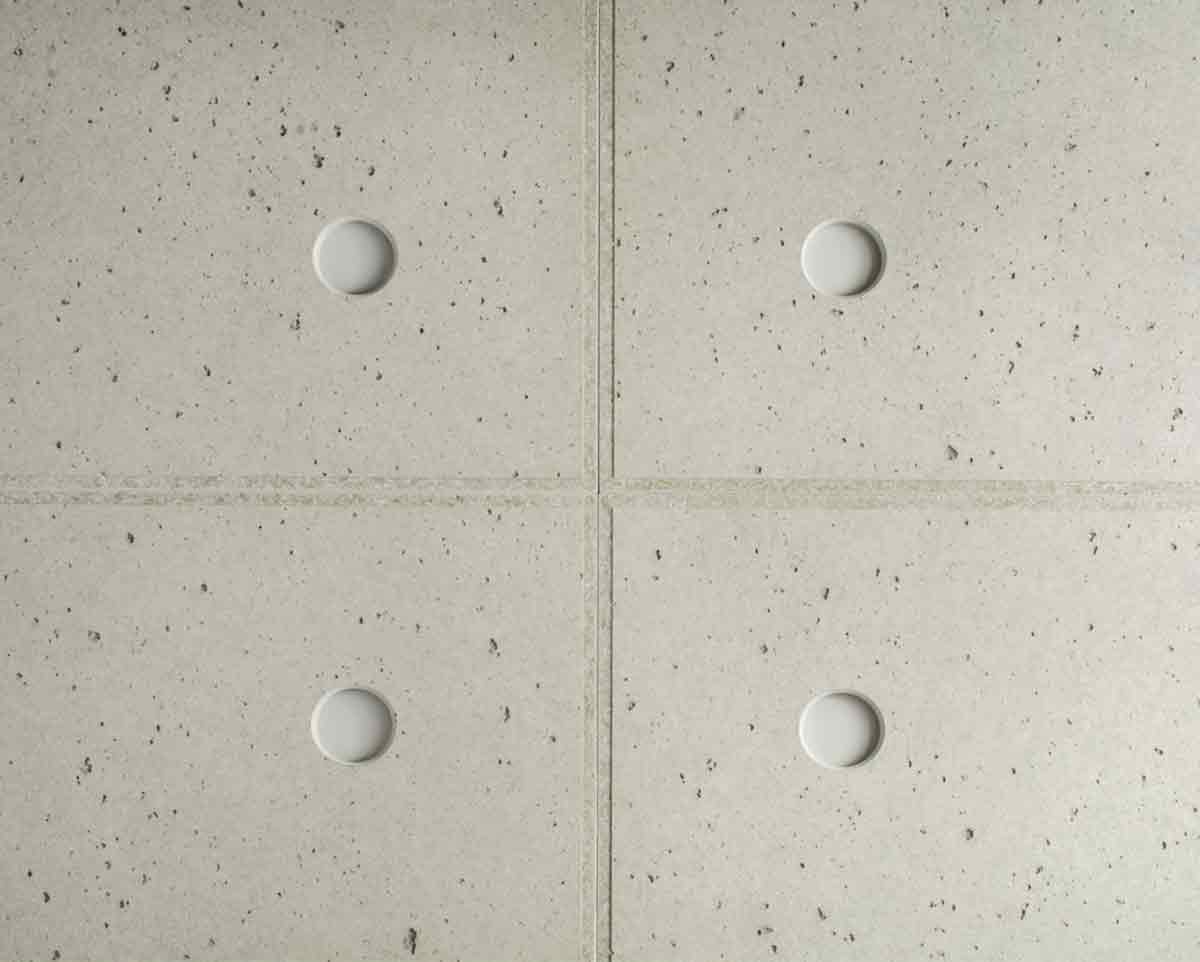

Lightweight Concrete Formwork

The Formwork panel consists of a 16 mm MDF board with a 1.5 mm concrete panel on both sides. This panel has a unique authentic concrete look.

Lightweight Concrete Pur

For further application, we offer a pure concrete slab of 1.5 mm or 3 mm for direct gluing. Bonding of these pure concrete slabs can be done with dispersion adhesive, contact adhesive and reactive resin according to the manufacturer’s instructions. Also ideal for temporary use at trade fairs and exhibitions.

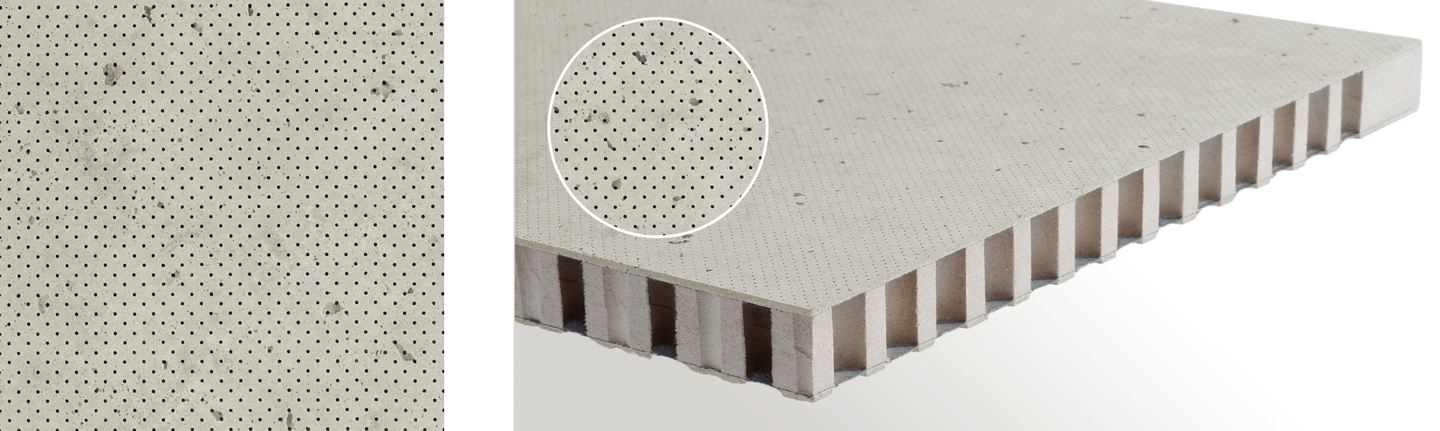

Lightweight Concrete Acoustic

Acoustic Trend has developed the Lightweight Concrete Acoustic panels especially for improving the acoustics. These are panels of recycled light material with a 1.5 mm concrete slab on both sides with micro-perforation on the front and acoustic felt on the back.

Finishing concrete wall panels

The outer concrete layer consists of cement and mineral fibers that have hardened into a hard limestone. With some basic knowledge, the material is easy to process. If you would like to know more about the options for processing the concrete panels, please contact us!

Seal

All standard concrete panels are factory pre-painted with our water-based two-component acrylic sealant ‘WBAS 1993’. The panels for vertical applications on walls and the furniture sector are thus protected against contamination. When the panels are applied horizontally and are subject to greater wear and stress, the panels must be fully coated (including the edges) after processing.

Edges

The standard panels can be chamfered with an edge banding machine. The 1 mm LightBeton® and ABS edges are available as standard.

Milling, chamfering and rounding

The panels, which are provided with a homogeneous concrete cover layer of 1.5 mm on both sides, are easy to process. Think of milling/shaping, chamfering and making roundings.

Gluing

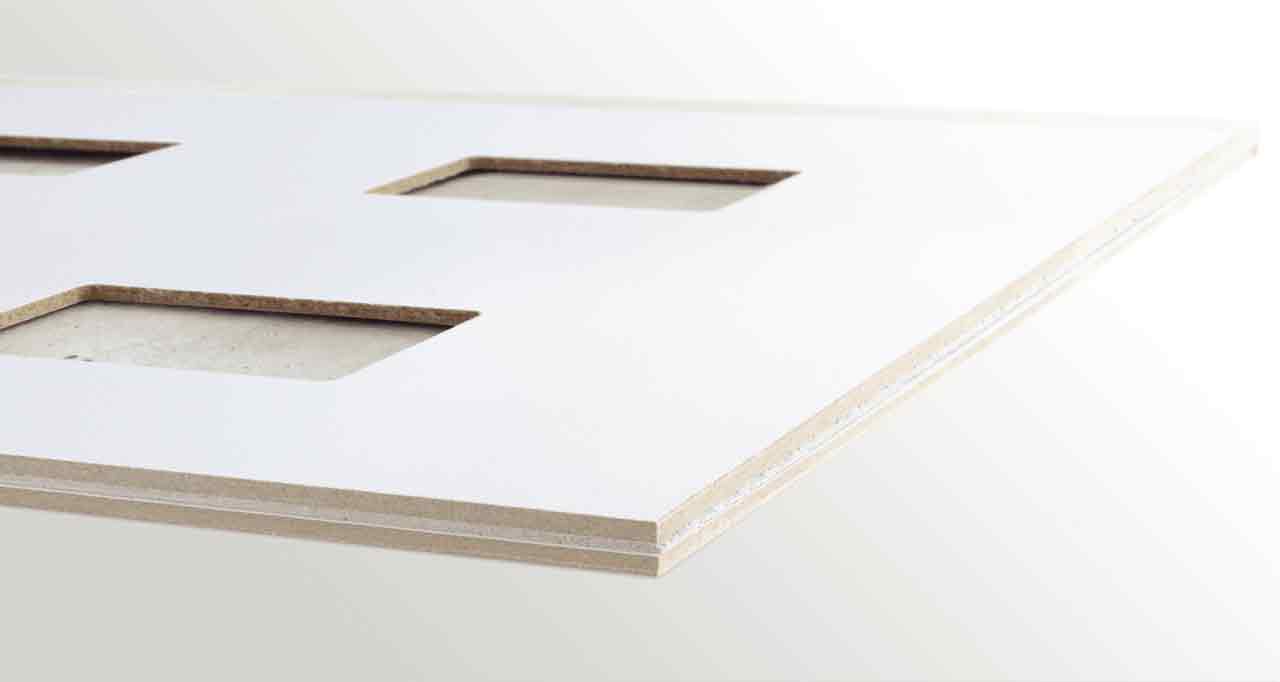

The gluing of the Pur concrete slab can be carried out with dispersion adhesive, contact adhesive and reactive resin according to the manufacturer’s instructions. The two slave boards with viewing windows provide protection during transport and help support the cut sheet.

Fronts

For free-standing applications, such as fronts, a PUR concrete slab is required on both sides. In the factory, all standard panels are glued on both sides on a 16 mm thick MDF board. All panels are fire resistant and fall under the fire protection consolidated certification B-s2, d0. The processor is responsible for checking whether the concrete products are suitable for the intended application.

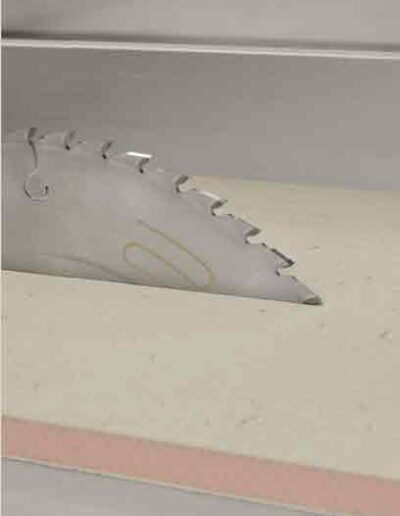

Tools

Lightweight concrete can be processed with all standard carbide tools used in the woodworking industry. Saw blades with alternating teeth are preferably used for cutting the material. For optimum cutting and milling results and longer tool life, cutting speed and feed must be adjusted as necessary.

Repair-Mix

With the REPAIR-MIX repair set, minor damage such as scratches and holes on the concrete surfaces can be repaired easily and almost invisibly.